METAL WORKINGAT KENTUCKY MOVERS AND MAKERS

|

GHB-1340A Lathe With Newall NMS300 DROWhat is the Metal lathe used for?

A metal lathe, on the other hand, is a type of lathe that’s capable of performing metalworking applications. Because metal workpieces are harder than wooden workpieces, metal lathes are extremely powerful. They are able to aggressively manipulate and deform workpieces made of steel, iron, aluminum and other common metals. Also known as a metalworking lathe, it’s a powerful machine that’s frequently used in manufacturing applications involving metal workpieces. Metal lathes are used in conjunction with a hardened cutting tool that’s secured to a rotating mounting surface. The metal workpiece is stationed on the lathe, after which the hardened cutting tool presses against it. Video Tutorial

|

MBS-1018-1 , 10" X 18" HORIZONTAL DUAL MITERING BANDSAWWhat is a Horizontal Duel Mitering Bandsaw used for?

It is used to cut at multiple angles in both directions. This dual-mitering band saw has a cast iron head and bow that can swivel 60° right and 45° left. |

|

What is a step pulley machine used for?

A step pulley is a system of pulleys made up of many different sizes. The typical step pulley consists of a two- to four-pulley configuration. This type of step pulley is found on equipment such as a drill press where different operational speeds can be produced simply by changing the belt to a different pulley size. |

What is a manual cold saw used for?

Cold saws provide extremely high cut quality in a fast and efficient operation by way of their coolant system and low RPM blade speed. Perfect for tube cut off, the blade machines it's way through the material leaving a smooth, burr free finish. |

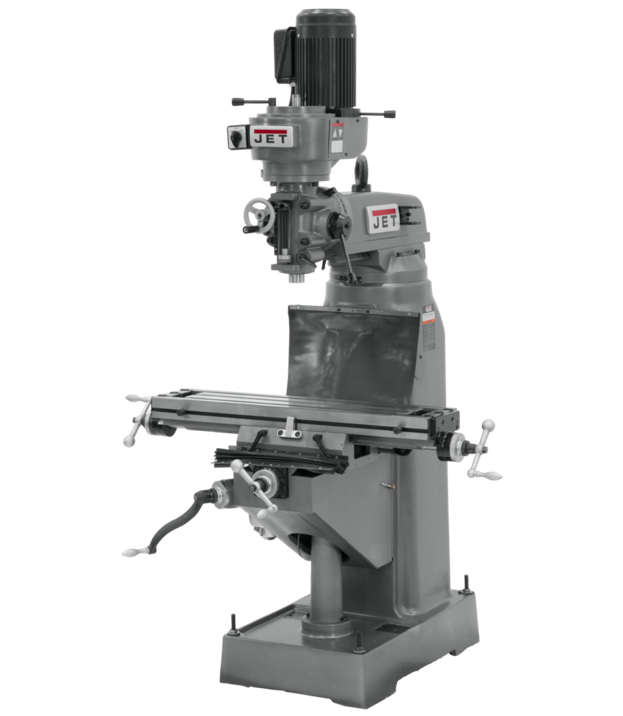

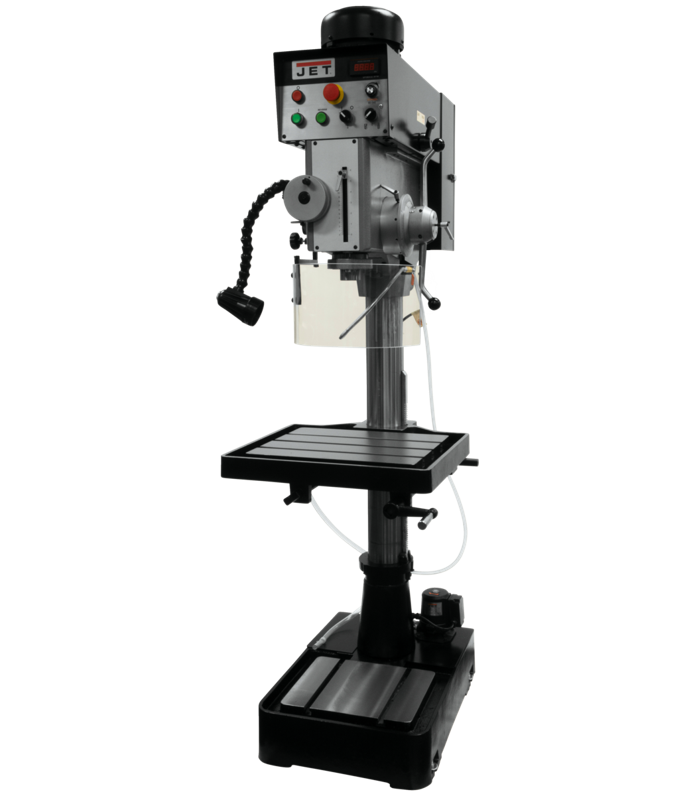

JDP20EVST-230-PDF, GH POWERFEED, 2HP, 3PH, 230VWhat is a drill press used for?

Accuracy is the main reason why woodworkers use drill presses. Of course, you can make holes in wood with standard hand-held drills, but you can't make identical holes. A drill press allows you to set the precise depth, angle, and width of each hole. |

CNC PLASMA TABLEWhat is a plasma table used for?

To properly explain how a plasma cutter works, we must begin by answering the basic question “What is plasma? In its simplest terms, plasma is the fourth state of matter. We commonly think of matter having three states: a solid, a liquid, and a gas. Matter changes from one state to the other through the introduction of energy, such as heat. For example, water will change from a solid (ice) to its liquid state when a certain amount of heat is applied. If the heat levels are increased, it will change again from a liquid to a gas (steam). Now, if the heat levels increase again, the gases that make up the steam will become ionized and electrically conductive, becoming plasma. A plasma cutter will use this electrically conductive gas to transfer energy from a power supply to any conductive material, resulting in a cleaner, faster cutting process than with oxyfuel. The plasma arc formation begins when a gas such as oxygen, nitrogen, argon, or even shop air is forced through a small nozzle orifice inside the torch. An electric arc generated from the external power supply is then introduced to this high pressured gas flow, resulting in what is commonly referred to as a “plasma jet”. The plasma jet immediately reaches temperatures up to 40,000° F, quickly piercing through the work piece and blowing away the molten material. |

30" Metal shear, press brake & slip roll

|

This versatile shear, press brake and roll machine lets your cut, form and roll all with one tool! The shear makes straight cuts up to 30 in. wide while the press brake makes bends to 90 degrees in material up to 30 in. wide. This 3-in-1 roll machine also includes adjustable finger dies for pans and boxes of varying sizes making this unit essential for any metalworking shop.

|

|